Divisions

HEALTHCARE

Innovative technologies allow production of complex devices to combine

more and more functions in miniaturized systems. This is crucial in

medical technology and it’s why Metallux partners up with its customer

from the early stage of development and design up to

industrialisation of its devices. Guidance throughout the entire

product life cycle takes into account the strict requirements in terms

of safety, reliability and functionality yet complying with medical

stringent regulatory requirements.

Healthcare

applications

applications

We guide our partners from feasability to industrialisation and bring

the projects to the market by providing electronic manufacturing

services (EMS). Our client portfolio includes well structured and

known large multinational companies as well as start-ups that want to

approach the market, who need to develop, engineer and produce their

idea.

01.

Contract manufacturer

- Full Service Medical Device Contract Manufacturer

- Turnkey integrated devides

- Assembling (from Manual to Fully Automatic Lines)

- On lines testing (Electrical, Pneumatic, Functional)

- Custom sensors and electronics

- Clean room ISO7 of DNA/RNA free and DNase/Rnase free

- Molds and molded parts in ISO7 clean room

02.

Proprietary products

-Pressure sensors

-Hemodyalisis M. D.

-Regenerative medice

-Orthodontics MD

-Hemodyalisis M. D.

-Regenerative medice

-Orthodontics MD

01.

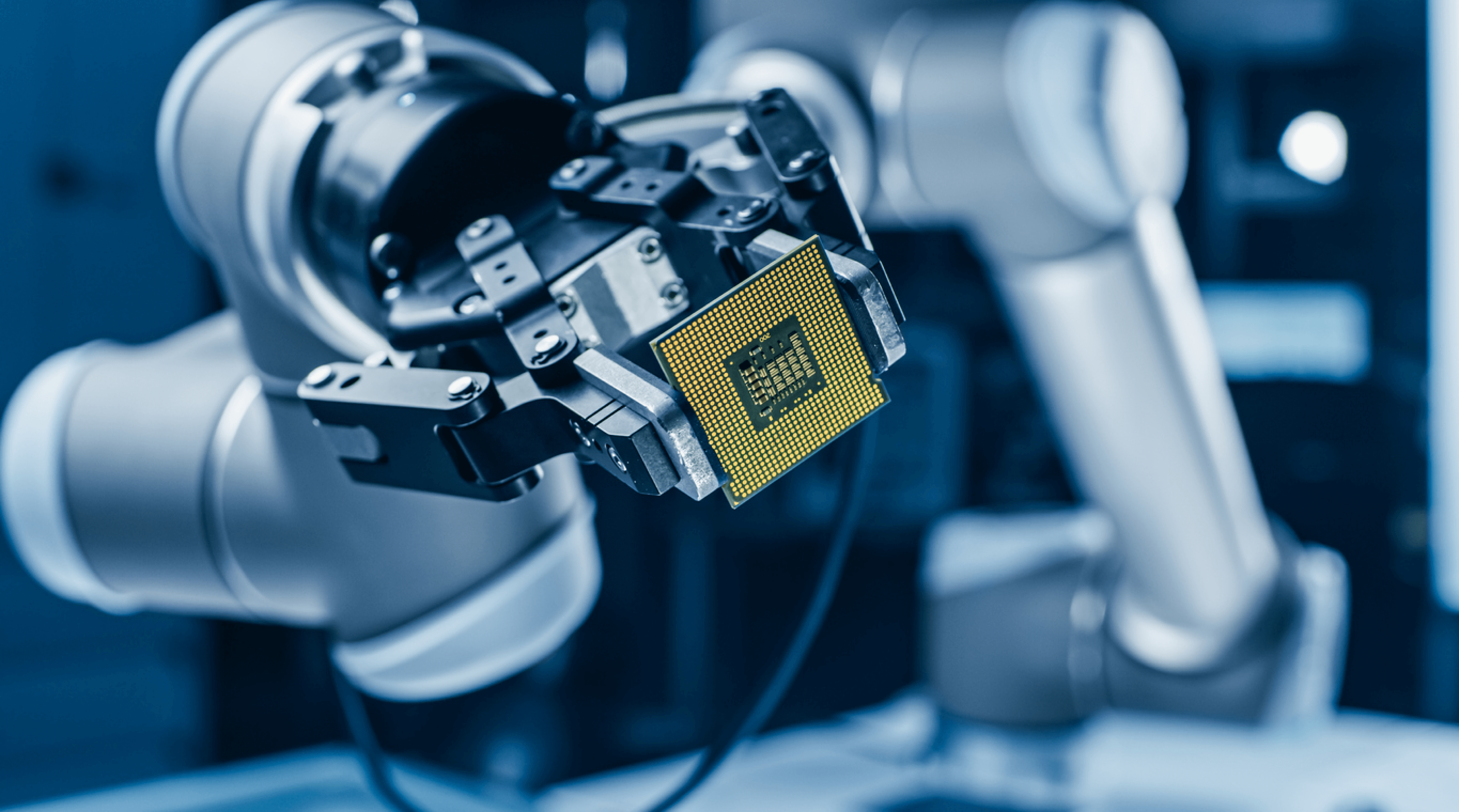

Miniaturization

We offer our customers comprehensive expertise in electronic

miniaturization for innovative medical devices. Smaller devices enable

less invasive procedural techniques and therefore less trauma during

surgery and other medical procedures. Innovative tiny active implants

enable a huge advance in challenging health problems such as diabetes

management, deep brain stimulation and chronic pain relief.

02.

Assembling

The industrialization of complex medical devices requires exceptional

conditions. In order to produce and assemble various components in

compliance with stringent high quality and safety parameters, it is

necessary to rely on companies you can trust, Metallux has invested in

people, skills and equipment to deliver consistent and competitive

growth. Metallux tailorizes production processes in compliance with EN

ISO13485 requirements and specifications, offering dedicated production

lines even in a clean room environment.

03.

Pressure sensors

Metallux designs and manufactures pressure transducers, for a wide

range of applications in the Medical. Our transducers are designed to

achieve high accuracy and minimize long-term drift.

Metallux produces pressure sensors for:

- Blood lines,

- Catheteres , probes,

- Dialisys,

- Special sensors

Metallux produces pressure sensors for:

- Blood lines,

- Catheteres , probes,

- Dialisys,

- Special sensors

The range of services offered by Metallux include feasability

analyses, development, support, technological product design,

prototyping, series production, qualification procedures.

04.

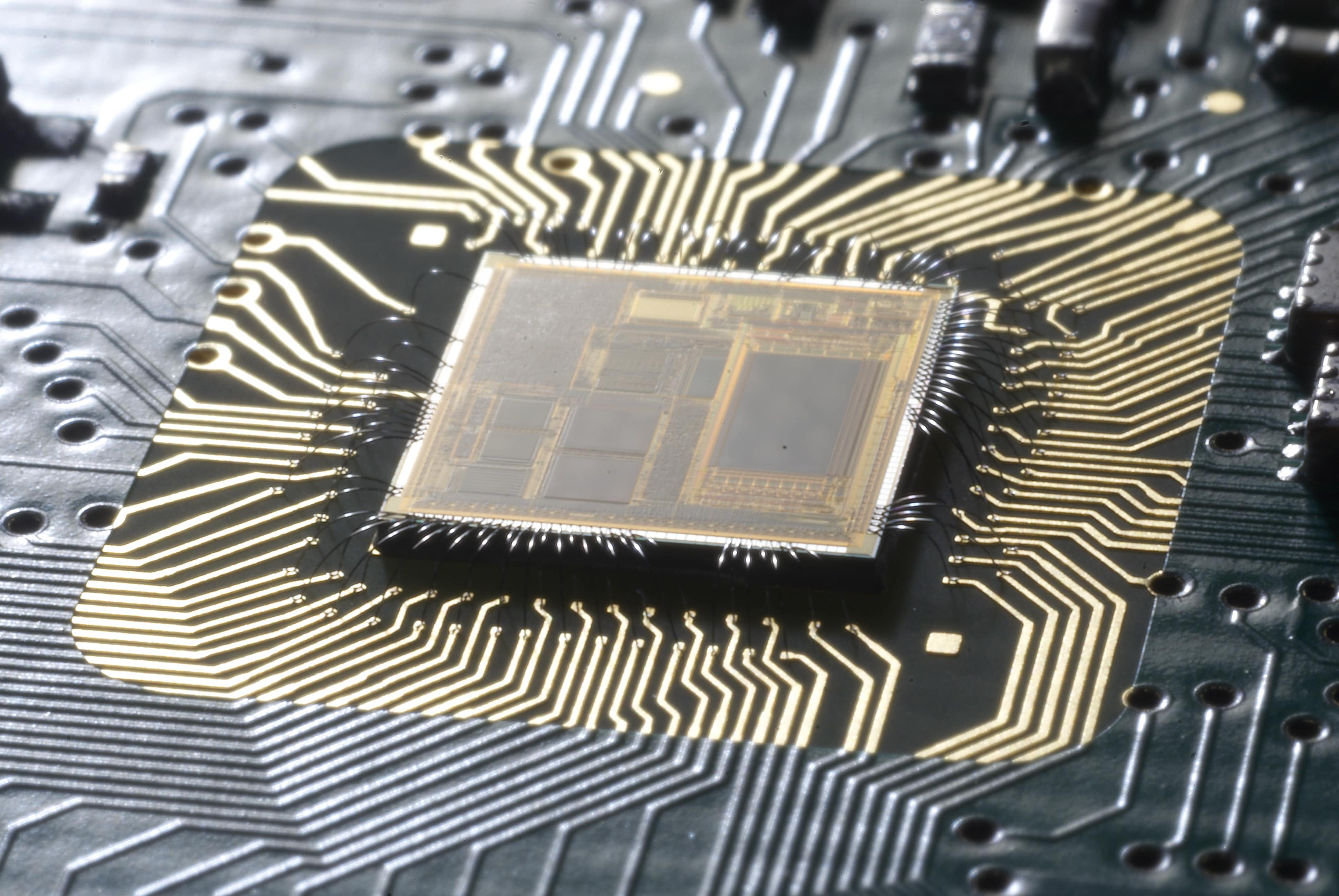

Electronics and microelectronics

Electronic circuits manufacturing

- Thick film technology IPC compliant

- Substrates: AL203 ceramic, ALN,

stainless steel, sapphire, FR4, flex

- Multi-layered and hybrid circuits

- Die attach

- Ball and wedge bonding

- Chip-on-board

- Surface mounting technology

- Encapsulation

- Assembly

- Customization

- Thick film technology IPC compliant

- Substrates: AL203 ceramic, ALN,

stainless steel, sapphire, FR4, flex

- Multi-layered and hybrid circuits

- Die attach

- Ball and wedge bonding

- Chip-on-board

- Surface mounting technology

- Encapsulation

- Assembly

- Customization

05.

SMT production lines

From SMT production lines to PCBA assemblies Metallux offers its

technical expertise and the manufacturing capabilities:

- Automated SMD line

- Chip On Board

- Reflow line

- Automated visual checks

- SMT assembly on Ceramics, PCBs, Flex Prints and other kind of substrates

- SMD components form 0201, BGA, µBGA, QFN, Flip Chip, etc.

- Automated SMD line

- Chip On Board

- Reflow line

- Automated visual checks

- SMT assembly on Ceramics, PCBs, Flex Prints and other kind of substrates

- SMD components form 0201, BGA, µBGA, QFN, Flip Chip, etc.

06.

Molds and molded parts

Contract Manufacturing for design, mould making, moulding and packaging,

also in Clean Room (ISO Class 7) of complex parts. The customer is also

supported in the choice of the thermoplastic polymer suitable for the

specific project, in order to obtain the best optimization of the mould

design

07.

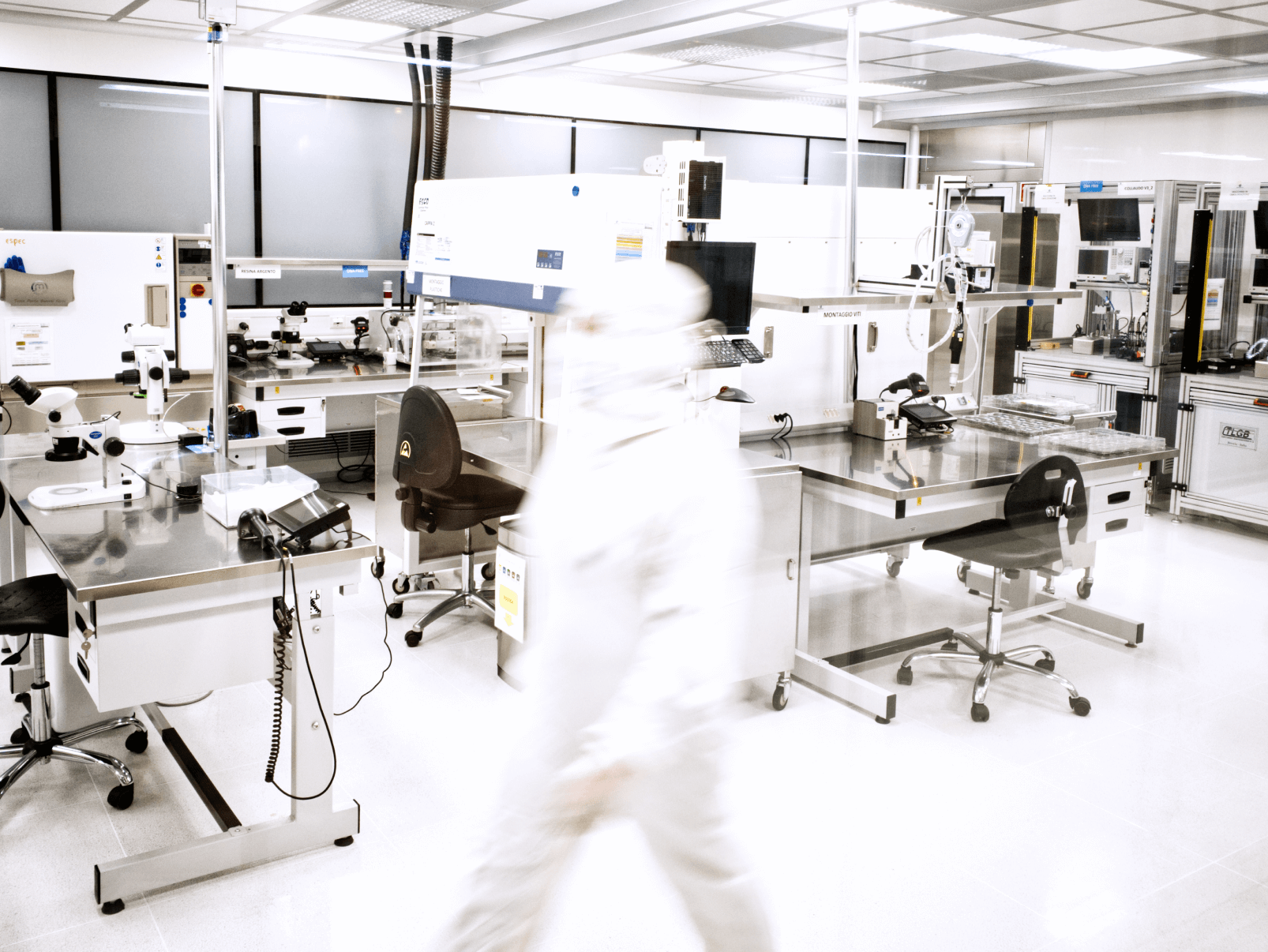

Clean room ISO7 and ISO8

Metallux offers its capabilities on: Assembling of medical devices

Sterile MD with validation of the sterilization process Special process

in “DNA & RNA Free” Clean Room SPECIAL PROCESS: DNA and DNA ase free RNA

and RNA ase free

Our

Process

Process

Metallux follows the customer from the idea, through feasibility

analysis and project development to industrialization and production.

Your turnkey products assembled in a RNA and DNA free chambers.

Your turnkey products assembled in a RNA and DNA free chambers.

01.

Feasibility analysis

We will analyse the project's relevant factors in cooperation with the

customer including economic, in order to complete the project

successfully.

02.

Project development

Each project is assigned to a product manager who handles all stages

of product development, monitoring compliance with the technical

specifications received, quality standards, costs and timelines.

03.

Industrialization

We customize production processes according to customer requirements,

offering dedicated production lines.

04.

Manufacturing

We believe in flexibility, which allows us to adapt quickly to our

customers' needs with a defined and shared time to market.

Healthcare case studies